Scott Locklin works on quantitative finance problems in Berkeley, California, but has lately been considering emigrating to America. He blogs at Locklin on Science.

British engineering is one of those things which periodically fascinates and repulses me. Their engineering unquestionably has a national character, just like their Wensleydale cheese and bitter ale does; it is part of their national culture. It is also one of those things which I can’t seem to escape from, like crazy ladies and computers.

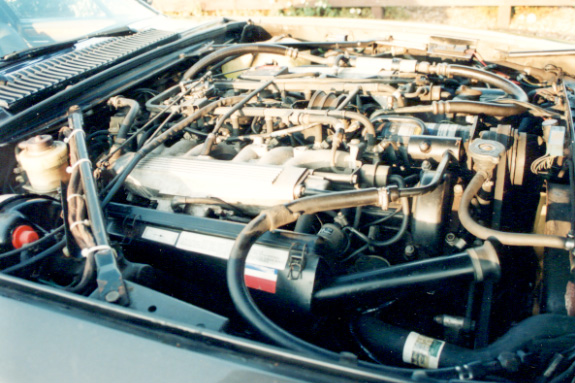

Just take a look (with all that spaghetti, you’d think it was Italian):

I have quite a bit of professional experience with British engineering, which I won’t bitch about here, because bagging on your former co-workers is poor form. Instead, I’ll pick on the Jaguar XJS; a car I periodically consider buying.

The salient feature of British engineering is its Byzantine nature. It will have every knob, gear and deelybopper invented. It will have them in most inaccessible places. While some British engineers may be detail-oriented, anal-retentive types who go over their designs with vernier calipers to make sure everything is perfect, I suspect all of those engineers are unemployed Scotsmen. The English ones running things are almost certainly all Thomas Dolby-looking eccentric boffins; alternately brilliant and forgetful.

British designs will require constant intervention and maintenance by highly skilled and trained technicians on a regular basis, yet they will be designed in such a way as to make these interventions as difficult and labor intensive as possible. In fact, the budget will generally explicitly prevent the labor from being hired. Parts central to the design will be made of insane unobtanium materials which will never break. Parts peripheral to the design will be made of junk and will break often. Peripheral systems fail so spectacularly they may manage to ruin the central unobtanium feature. For example, most XJ-S jaguars are destroyed by combination of a cheap screen in a badly designed fuel system, and a worn spring in the distributer causing a lean condition and overheating which melts the overdesigned alloy pistons. Another clever one: there is an exposed and completely unnecessary body rivet which eventually rubs a hole in the cheaply made gas tank. If you’re lucky, the resulting hole merely compensates for the cheap screen in the fuel system and prevents you from blowing out pistons. If you’re not, your car will burn.

Then there is the little matter of the Prince of Darkness; Lucas, who designed the electronics for every major British car maker. You’d think they would have farmed it out to someone with a better reputation after the first couple of misses, like the Yugoslavians, or Rockwell. Nope.

These flaws remained for the entire lifetime of the XJ-S design: from 1972 to 1996. English people do not like fixing design flaws. That’s for peasants. In fact, those goddamned peasants had better not mess with the original design, because the designers never really quite believe those design flaws are really flaws rather than strokes of brilliance. Probably the dumb user screwing something up. By the way, another salient feature of British engineering; in fact, what is probably responsible for the downsides of such is British management. Ever watch Monty Python? Ever study the history of the British WW-1 officer corps? Does the phrase “lions led by donkeys” mean anything to you? Enough said about British management.

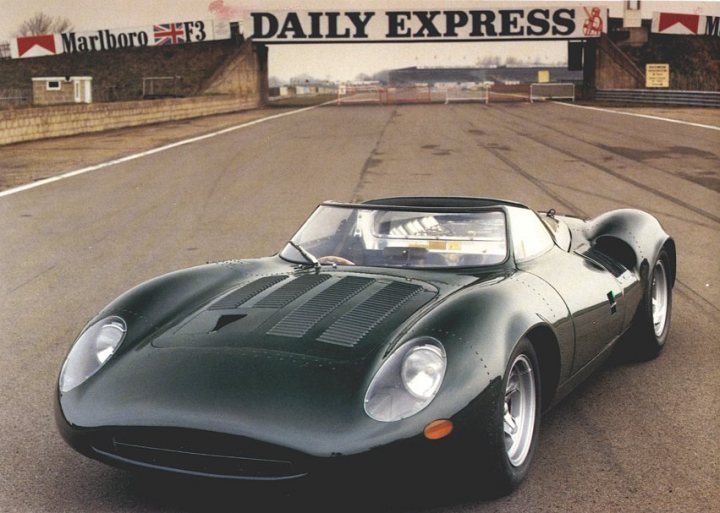

The question naturally presents itself as to what the attraction to such things are in the first place. Well, when they’re on, they’re really on. English things have panache. They have style. From their clothing, which is pretty much the pattern for gentleman’s clothes all over the world, and has been since King Edward, to their cars, to their spectrometer designs. That’s some cool, flashy stuff man. When it works right, it is totally badassed and beautiful.

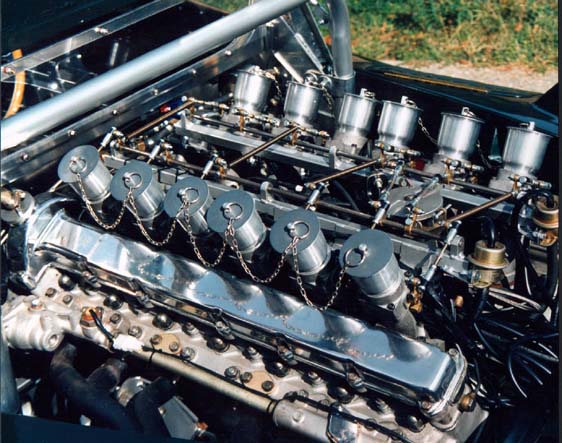

The engines, like the hearts of most English designs are plain old art. They are poetry in steel and aluminum. Even where they screw up the motor (like in the early XKS engine’s retarded use of 1930s era flat heads; hey it only got 8mpg, but it HONKED) they’d fail in a way which was interesting and fixable (spending a half million pounds to clone an american head design netted another 30 horsepower and 19 mpg in the same engine). Looking at the things reminds one of nothing more than an incredibly powerful aircraft engine. Looking at American motors, well, you’re looking at something unimpressively functional, more suited to powering a tractor than a motor car. Sure, the British engines are a bear to tune. Sure, they can blow up because of dumb upstream details that costs pennies. But they sure do look cool.

It is amusing to contemplate what would happen to the Jaguar if they gave it Japanese management. Ford was the wrong choice for certain. No limey worth his mushy peas will seriously listen to Americans. Tolerate ‘em, take their money, but don’t take them seriously, old fruit. I can’t even imagine what is happening over there now that Tata owns them; it’s painful to even contemplate. Really, what needed to happen is you need to give an English designer full creative license to make nifty engines and swoopy doodads for the car, and let some detail-oriented Japanese types make the rest of the thing, and do the overall engineering to make sure the whole enchelada works together. The Japanese are good at that. I’ve never really seen a Japanese mass produced design with a lot of panache and dash like English (or Italian) designs, but they are good at details and integration: pretty much the best nation in the world for this sort of thing. I think it’s because a Japanese engineer can take a lot of pride in doing something pedestrian like making sure the gas tank won’t get holes worn in it by rivets. Consider the attention to detail given to small things in a Japanese sword; mind boggling, really. Englishman can’t be bothered with such trivialities; it interferes with his eccentric Mozart act. Lotus, Austin Healey, Spitfire, MG: junk junk junk. But cool, boffinish junk.

The apocalypse that British engineering became was caused by a cultural shift, the talent was always there, little incentive to bring it out of it’s box, the ‘clever’ money departed circa 1900. If I respond, at a party in Germany to the question “job?” with…”retired engineer” nobody backs away, here in the UK….puzzlement.

There is far more to engineering than the automotive industry but now sadly, much diminished. You mention names, bywords for sloppy, untrained management and death wish trade unions, you could add British Shipbuilders, the list would be endless. Nothing junk about today’s Lotus however, full order book, a major design company.

Your suspicion that Scotsmen are detail wonks is delusional, possibly brought on by over exposure to Star Trek.

I shall tell you a story, a salutary tale, I ran a company, one of the customers was a ginger bloke, the C5 ginger bloke, ex Texas Inst employee, got in on the ground floor of the embryo HiFi industry, sold diy amps and tuners, we made the stuff for him, couldn’t pay his bills “you can have your bits if you bring a cheque”, sitting in my office one day, in he walks, brings out a little gadget “try that”, “wots that Clive”, “it’s a cal..cu..la..tor”, remember, until then, slide rule, ready reckoner, adding machine

“F..k me”, I thought, eureka, a new dawn. One week later it deep sixed itself after numerous attempts at working the tiny buttons, with a pencil point. It was a commercial abortion, some months later the Japanese flooded the market with working models then HP introduced the 35.

Tut tut ginger nut’s company at the Old Mill, via splinter groups, founded the English HiFi industry.

Strangely, there are more English designers, worldwide in the automotive industry than any other race. Except Detroit of course, where designers do not seem to be employed at all.

This marvellous post and then Malty’s comment got Tuesday off to the best possible start. It’s all downhill from here..

Well, the Scottish engineer thing was more of a joke than anything else: everyone knows that a detail oriented British engineer is probably some kind of German import. The Scots I have worked with are more along the lines of, “fix the Englishman’s design with epoxy and bits of string.” Still, they were all pretty remarkable at making things work. One of them fixed a 15 million dollar (British designed) spectrometer I was trying to make go with a crowbar and some bits of cardboard. Much like your manky calculator, it didn’t last long, but long enough for me to find something better to do.

As I said over at Scott’s place I suspect the nature of British engineering achievements has something to do with the British tradition of individualism: we tend to be much better at maverick boffinry than the stuff that requires carefully coordinated team work across lots of different sorts of people – and you need the latter if you’re going to create lots of sizeable, efficient and reliable manufacturing businesses.

However, proving that culture decisively influences economics is very difficult. In fact, Geoffrey Owen, who used to be editor of the FT, wrote quite a persuasive book about post-war British manufacturing that put most of its problems down to having to shift from protected imperial markets to more competitive international ones. And don’t forget that as a % of GDP the British manufacturing sector is as big as France’s (I think).

I actually think the British manufacturing sector is a little bigger than France’s as a % of GDP. Also, in 2007 twice as many cars were produced in the UK compared to the early 70s. It’s just that we need the Japanese to tell us how to do it properly.

Yes, as Toby says: British manufacturing was the 6th biggest in the world in 2007, behind the USA, China, Japan, Germany and (just) Italy. Ahead of France, Canada, Spain, Brazil and Russia.

One of the reasons that lead people to think that “we don’t make things anymore” is the hidden nature of many of the UK’s commercial hubs these days. I spent part of last year surveying Japanese-owned plant – loads of it is in the middle of nowhere, greenfield sites, or tucked away from English eyes in rarely-visited corners of Wales (whose inhabitants would describe parts of England in the same way, I’m sure).

So much pre-1980s manufacturing took place in and around industrial urban cities like Sheffield that when that went and wasn’t obviously replaced, we assumed it had gone altogether. And yet, by value, we manufacture more than we ever did. However, manufacturing as a sector has grown far more slowly than other sectors, so it’s overall share falls when its still getting bigger.

Curious that, the league tables, need to have an inspectorial optic cast over them, the market capitalisation of Siemens is worth more than the entire British manufacturing base. The world of the German SME’s is vast, well funded, owes nothing to the money changers and is suffering a minor skill shortage. The British SME world is tiny by comparison, even with the Italians, drive from Milan to Bergamo and start counting or from Stuttgart to Wiesbaden and weep.

George Osborne wants to make Britain “the best place in Europe to start, grow and finance a business” apparently…

Will Osborne be writing a screenplay about tbp in Europe and will it be called ‘and watch it come down, the sequel’

where does Jonathan Ive fit into all this?

Neal Stephenson’s Cryptonomicon, one of the great literary comedies of the last few decades, is nowhere funnier than when describing British engineering:

There is no in-between with these people. You have to walk a mile to find a telephone booth, but when you find it, it is built as if the senseless dynamiting of pay phones had been a serious problem at some time in the past. And a British mailbox can presumably stop a German tank. None of them have cars, but when they do, they are three-ton hand build beasts. The concepts of stamping out a whole lot of cars is unthinkable — there are certain procedures that have to be followed, Mr. Ford, such as the hand-brazing of radiators, the traditional whittling of tyres from solid blocks of cahoutchouc….

(Our hero enters a meeting)

“Was something said, a few minutes ago, about the availability of coffee?” Waterhouse says.

Miss Stanhope, coffee for Captain Woe To HIce,” says the Main Guy into an electrical intercom. It is one of only half a dozen office intercoms in the British Empire. However, it is cast in a solid ingot from a hundred pounds of iron and fed by 420-volt cables as thick as Waterhouse’s index finder. “And if you would be so good as to bring tea.”

brilliant stuff David!!!

Once upon a time I owned a 1957 MGA; later a 1975 TR-6.

In engineering terms, despite the nearly two decade difference in ages, there was roughly the square root of heck-all difference between the two of them.

—-

Perhaps not oddly, given the thesis of the post, nearly all F1 racing teams are headquartered in Jolly Old.

More difficult to explain, though, is that Rolls Royce is one of the world’s premier jet engine manufacturers.

Here in the colonies, we’re perpetually confused by the whole “largest manufacturing” award. Nobody has a factory job any more, and virtually every object (exception: cars) we come in contact with in our everyday lives is made overseas: generally in Asia. I strongly suspect that these figures are massively skewed by nonsense economics. For example: America makes huge quantities of junk food. Does slapping together a big mac or extruding milk duds count as “manufacturing?” Does processing grain or beef or milk containers count as “manufacturing?” Is software manufactured? I know there is a tax deduction for software manufacture, as I take it every year, but I don’t think it is manufacturing by any reasonable definition of the word. There must be some kind of “non perishable manufacturing” category we’re failing at.

And … addressing a point about the Lotus: the new one seems to be pretty good, even if it is technically owned by the Malays. The older ones: well, they’re very British.

Further afield on the Malay topic: I stayed in a magnificent hotel in Penang with colonial era GEC electricals. The bakelite rheostat which controlled the ceiling fan looked like something from a Thomas Dolby video. I’m pretty sure it will be there in 200 years.

http://i53.tinypic.com/x2p0k5.jpg

Scott, the subject, excellently highlighted by yourself, is one that most influences my Victor Meldrew juices, Being long in the tooth and having been there, seen it and got the dinosaurs medal I shall, the taters now being planted and it’s raining, tell you another story.

Gaw correctly points out one of the causes of decline, the captive market syndrome, this had a major influence on manufacturing but is still simply a spin off from the collective mindset problem.

What follows gives some inkling into why the engineering manufacturing base, suffering from influenza when New Labour were thrown in, had contracted bowel cancer by the time they were thrown out and is why I simply do not believe the statistics, someone is telling porkies, the media’s knowledge of business is so poor that it constantly quotes profit as an amount of monies and says ‘look at these greedy pigs’ totally unaware of the fact that it is the profit margins in percentage terms that are the key figure. I doubt many of them can distinguish a balance sheet from a jelly tot.

This obituary although nearly one decade old and in places incorrect, and why not, it is after all The Guardian, bears reading and gives insight into the Labour government’s mindset. Of note is the phrase ‘New Labour’s bridge to business’ that would be the Hohenzollern bridge at Remagen then. This mindset stretches back to the beginnings of the Wilson government and is the reason for the current state of play within manufacturing, the Tories had ideas but poor implementation skills, Labour were, are and forever will be utterly, hopelessly useless at setting the groundworks for a healthy manufacturing environment and that is all any government should do, create the conditions and then eff off and mind their own business.

The obituary is for one Gerald Frankel, I had mentioned in earlier comment running a company supplying Sinclair, for a number of years during the late sixties and early seventies Frankel and his companies, Caps Research and Imtech were our major customers, by a long way. The concept was brilliant, they more or less single handedly developed microfilm as a means of data storage and retrieval, in the days before the universal availability of hardware based computing, truly revolutionary. By any reasonable measure they should have become world leaders, going on and developing new, technology based products, they went bust, tits up, kaput.

Frankel’s forte was in marshalling the right forces for the inventors stage, head-hunting Europe’s best optical expert and an ad hoc collection of German, Burmese and Czechoslovakian development engineers. When it came to the really clever stuff, marriage of the strategic commercial with modern marketing and outsourcing techniques and iron filing fettling, clueless, head in the clouds, the company ending it’s days in the clutches of a Dutch office equipment company, eventually the door closed on Caps and son of Caps. As suppliers, it was an education as well as a bumpy ride.

That he was brought into New Labour and they sat at his feet and purred with admiration speaks volumes, that they went on and spread their legs for the money changers is well documented, that British manufacturing is an emaciated pitiful thing is a fact.

What lies ahead? technology as a saviour? unlikely, from where will come the revenues needed by government, the banks? service industry? As the inimitable Fred Dibnah once said ‘we are selling ourselves double glazing’. The aluminium supplied be Hoogovens and the glass by Schott,

Most of the jobs, along with the technology have been exported east, perhaps when the lawyers, money changers, doctoring and academics jobs are exported will this become a problem, them in charge are having to draw benefit, that’s a horse of a different hue.